Polymers

Podcast

Understanding Polymers: From Nature to Innovation

A polymer is a large molecule composed of repeating structural units called monomers, which are covalently bonded to form long chains. These macromolecules can consist of hundreds to millions of atoms, giving them unique physical properties. The study of polymers helps us understand both natural processes and the creation of advanced materials that revolutionize technology and everyday life.

Types of Polymers

Polymers can be broadly classified into two types: natural and synthetic.

- Natural Polymers:

- Proteins: These are polymers of amino acids essential for biological functions, such as keratin found in hair and nails, which has also been used in bio-sourced polymer materials [7].

- Nucleic Acids: DNA and RNA are natural polymers responsible for storing and transmitting genetic information.

- Polysaccharides: Examples include cellulose in plants, which provides structural strength, and glycogen in animals, which serves as energy storage.

- Synthetic Polymers:

- Plastics: Examples include polyethylene (PE) and polystyrene (PS). Polyethylene is one of the most widely produced polymers, used extensively in packaging, while polystyrene finds applications ranging from disposable cutlery to insulation [6][7].

- Synthetic Fibers: Nylon and polyester are common synthetic fibers utilized in textiles due to their durability and resilience [7].

- Elastomers: Synthetic rubber, like styrene-butadiene rubber (SBR), is an example of an elastomer used in products requiring flexibility, such as tires [9].

Polymerization Processes

Polymers are created through polymerization processes, which link monomers into long chains:

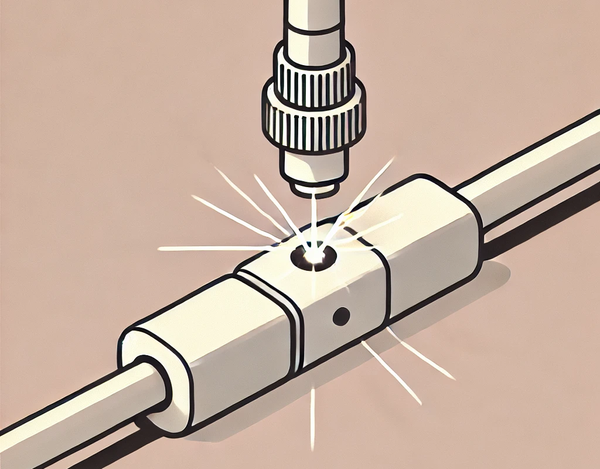

- Addition Polymerization: Monomers with double bonds add to a growing chain without by-products. Common examples include polyethylene and polystyrene [9].

- Condensation Polymerization: Monomers join together, releasing small molecules, like water, as by-products. This method is used for producing polymers like nylon and polyesters [9].

Properties of Polymers

Polymers exhibit diverse properties, making them suitable for a wide range of applications:

- Molecular Weight: A polymer’s molecular weight affects its strength, viscosity, and melting point. Generally, higher molecular weights lead to increased material strength and stability [8].

- Crystallinity: The degree of structural order (crystallinity) affects properties like density and transparency. Polymers with high crystallinity, such as high-density polyethylene (HDPE), are often rigid and durable [6].

- Thermal Behavior: Polymers are categorized as thermoplastics or thermosets:

- Thermoplastics (e.g., polyethylene) soften when heated and can be reshaped multiple times [9].

- Thermosets (e.g., epoxy) undergo irreversible hardening, making them suitable for high-strength applications [9].

Applications and Environmental Considerations

Polymers play crucial roles in various industries, from packaging and automotive to aerospace and medical fields:

- Polyolefin, such as polyethylene and polypropylene, are among the most widely used due to their versatility and recyclability [6]. They are used in everything from food containers to automotive parts.

- Elastomers like natural rubber are essential in products requiring elasticity, such as seals and tires. Elastomers have the property of stretching and returning to their original form, which makes them ideal for many engineering applications [7].

However, the environmental impact of polymers, especially non-biodegradable plastics, is a growing concern. The industry is focusing on improving recycling technologies and developing biodegradable alternatives to reduce their environmental footprint [6][9].

Understanding the basics of polymers—from their structure and properties to their diverse applications—offers insight into the ways these remarkable materials are integral to modern technology. Polymers’ versatility enables innovations across sectors, ranging from consumer products to medical devices and green technologies. For further reading on polymers, you can visit detailed resources like Essential Chemical Industry.

Are all plastics polymers?

Yes, all plastics are polymers, but not all polymers are plastics. Plastics are a type of material made from polymers that can be molded or shaped when soft and then hardened to retain that shape. Plastics can be either synthetic or semi-synthetic and generally consist of long chains of polymer molecules formed through polymerization processes. This flexibility in shaping, along with properties like durability, lightweight nature, and cost-effectiveness, has led to their widespread use in everyday items ranging from packaging to construction materials and medical devices.

Polymers, in general, refer to large molecules composed of repeating structural units called monomers. They can be natural or synthetic. For instance, natural polymers include substances like cellulose, starch, and natural rubber. Plastics, on the other hand, are specifically engineered polymers designed to have properties suitable for consumer and industrial applications, such as polyethylene (used in plastic bags) and polypropylene (used in fibers and containers) (Science History Institute, Wikipedia).

Thus, while all plastics are made from polymers, not all polymers are used to create plastics. For example, natural polymers like proteins or DNA play essential roles in biological systems but are not used as plastics. Additionally, other polymers are used in various forms, such as elastomers for flexibility or fibers for textiles, rather than molded plastic objects.

For more information, you can explore resources such as the Science History Institute and Wikipedia.