All about Steel

Podcast

An In-Depth Look at Steel

Steel is everywhere in the modern world—from buildings and bridges to tools, cars, and appliances. It's incredibly strong, tough, and cost-effective, making it one of the most widely used materials. But steel isn't just one thing; it's a complex system with a wide range of compositions and properties, allowing for a variety of uses across industries.

What Exactly Is Steel?

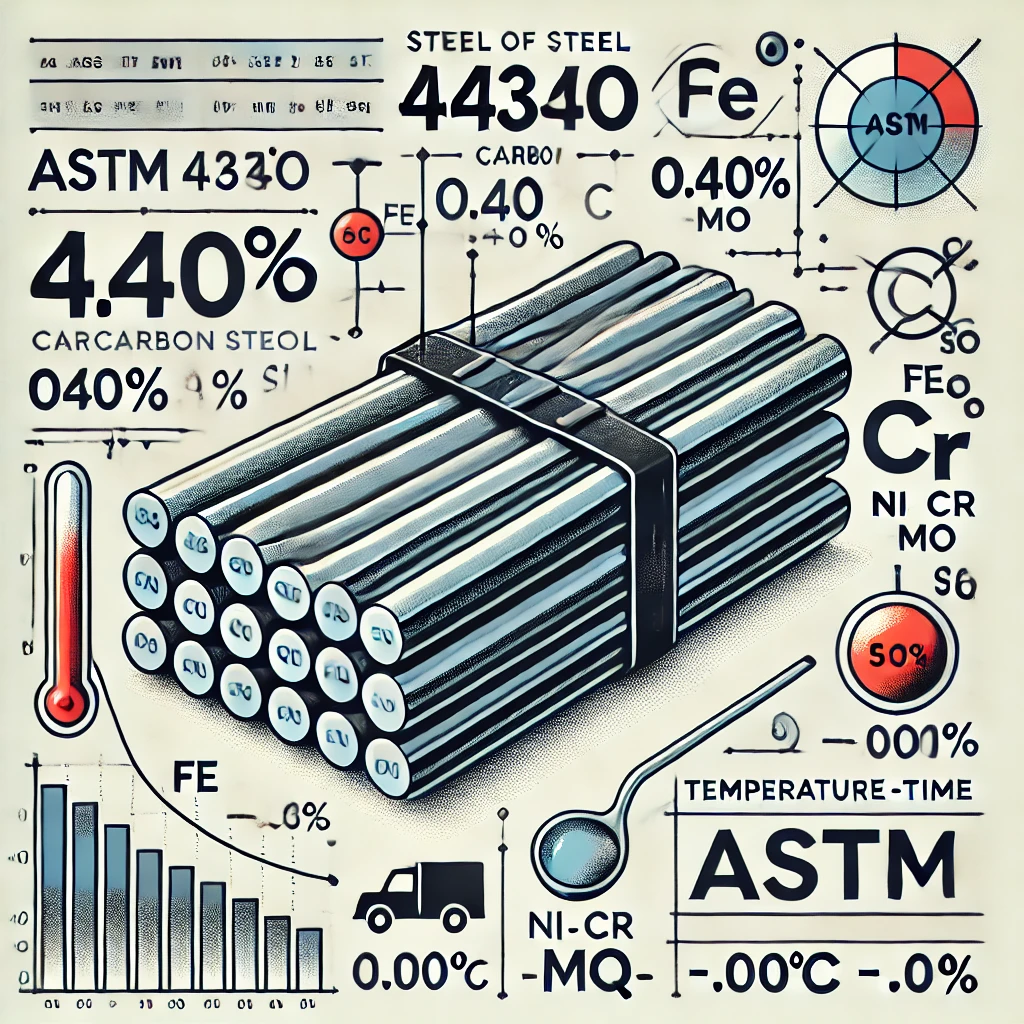

The simplest definition of steel is an alloy of iron and carbon, with carbon content between 0.02% and 2.14% by weight. Iron is the base metal, and its crystalline structure can change with temperature, giving steel its unique properties. Carbon acts as a hardening agent, giving steel its strength and hardness. But steel production goes beyond just iron and carbon—many other elements are added to achieve specific characteristics.

Why Add Other Elements to Steel?

While plain carbon steel is strong and tough, adding other elements can enhance its properties even further. Here’s how:

- Improve processing: Manganese is added to remove harmful sulfur from steel. Silicon helps molten steel flow better during casting, ensuring fewer imperfections.

- Enhance performance: Nickel and chromium boost strength and improve corrosion resistance, which is crucial for steel used in harsh environments. Molybdenum further improves corrosion resistance and is a key ingredient in stainless steel.

- Modify heat treat ability: Elements like molybdenum, chromium, and manganese can change how steel behaves during heat treatment, allowing for more control over the microstructure and properties of the final product.

Navigating the Complex World of Steel Grades

With so many different types of steel, choosing the right one for a specific application can be daunting. Here’s a quick guide:

- Carbon content: Steels can be classified as low, medium, or high carbon, depending on the percentage of carbon present. Low carbon steels are typically softer and more ductile, while high carbon steels are harder but less flexible.

- Alloying elements: Steels can be categorized as plain carbon (containing only carbon, silicon, and manganese) or as alloy steels, which have additional elements like chromium or vanadium to improve certain properties.

- Intended application: Steels are often categorized based on their use, such as structural steel for construction, tool steel for making tools, or stainless steel for corrosion-resistant applications.

- SAE grades: In the U.S., steel grades are often defined using the SAE/AISI system. For most steels, this system uses a four-digit numbering code: the first two digits represent the family of steel, while the last two indicate the carbon content. Stainless steels follow a different three-digit system.

Understanding the Impact of Processing Methods

The way steel is processed plays a major role in determining its properties and potential applications:

- Wrought vs. cast: Wrought steel is worked after casting, such as through rolling or forging, to align the grain structure and enhance strength. Cast steel, on the other hand, is shaped directly from molten form, resulting in uniform properties but less directional strength.

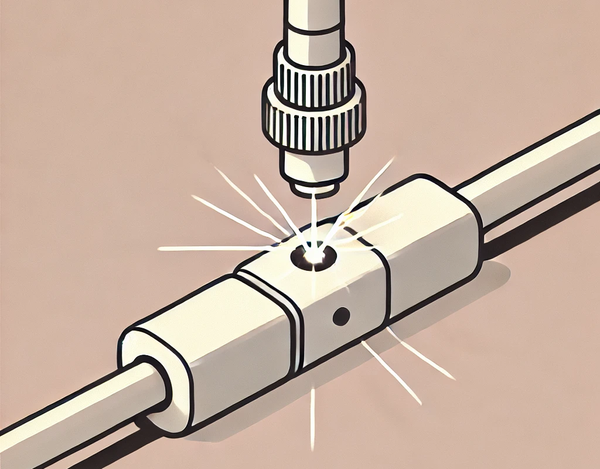

- Heat treatment: Processes like annealing, quenching, and tempering alter the microstructure to achieve specific mechanical properties—whether it’s softer and easier to work or harder and more wear-resistant.

Selecting the Right Steel: A Collaborative Approach

Choosing the right steel for any application isn’t just a matter of picking a grade from a catalog. Engineers and designers must balance performance requirements, cost, and processing limitations. Working closely with suppliers helps ensure that the selected material meets the necessary specifications and is the most economical option for the intended use.

The Future of Steel

Steel may be centuries old, but it’s still evolving. Researchers are continually pushing the limits of what steel can do. Advanced high-strength steels (AHSS) are being developed to make lighter, safer vehicles, and new heat treatment processes are emerging to further enhance steel's performance. Steel is versatile, adaptable, and still at the forefront of materials innovation—showing that even an old material can be made new again.